- Position:

- Chief mate

Subtleties in container ships

Based on the name, it is not difficult to understand that container ships are a specialized type of sea vessels designed to transport large-capacity containers. Today, one of the trends in logistics is the containerization of goods.

The emergence of container shipping has greatly increased the efficiency of transport processes, making it possible to organize the transportation of small batches of almost any type of cargo over thousands of miles.

Statistics show that container shipping provides for the movement of about 90% of the total volume of oversized cargo in the world, and container ships are one of the most common types of ships.

The main advantage of containers is the standardization of sizes, which simplifies not only their loading with various goods, but also their subsequent placement on board a ship or other types of transport. Against the background of an increase in the volume of container shipping and demand for them, there is a continuous increase in the size of container ships.

Compared to the first container ships operating at sea in 1968, modern ships have an average cargo capacity of 1200% more. Their technological sophistication and operational efficiency are also gradually increasing.

Types of containers

Large-capacity containers according to the ISO standard are universal containers for multimodal transportation, that is, they are adapted for transportation by various modes of transport, for example, after delivery by sea, the container with cargo is sent further by rail, and at the final stage of “delivery to the door” it is delivered by road.

At the same time, the cargo itself does not need to be reloaded along the entire route, it is reliably protected from negative atmospheric factors and theft.

For the convenience of organizing transportation, all containers are standardized in size.

By container length:

- 20-foot (6000 mm);

- 40-foot (12000 mm);

- 45-foot (a fairly rare type).

All containers are identical in width:

- 8 feet (approximately 2420 mm).

By height, all containers are divided into "low" and "high"

- the first have a height of 2600 mm,

- the second 2900 mm and provide a larger internal volume for the transportation of bulky but light cargo.

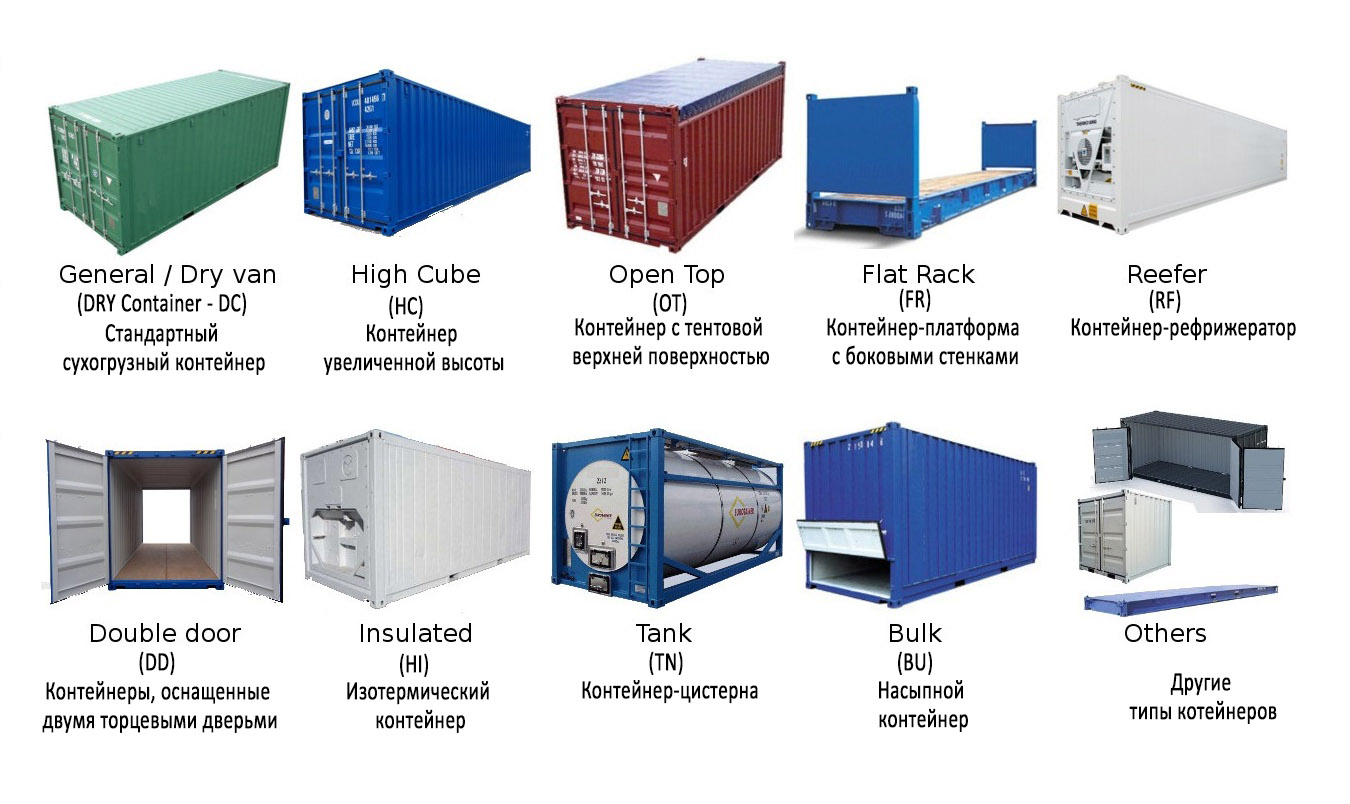

There are several dozen types of containers, of which the most widespread are:

Dry Van.

A universal container for a wide range of goods.

High Cube.

A high container with increased volume for various goods.

Open Top.

A container with a soft awning, allowing you to transport oversized cargo by height.

Refrigerator.

A refrigerated container for perishable and frozen goods.

Flat Rack.

An open cargo platform for placing almost any oversized cargo.

Tank container.

A cylindrical barrel for liquid cargo.

Side Open.

A container with an opening side wall for easy loading/unloading.

History of container ships

The introduction of container shipping has become one of the turning points in improving global logistics. Container ships have made it possible to transport a wide variety of goods around the world and created the prerequisites for sending consolidated cargo by sea.

Today, the market offers a large number of specialized companies focused only on container shipping and possessing the largest fleet in terms of tonnage.

The first container ships appeared in the 50s of the last century, but they were created for transporting containers of railway cars. Their loading/unloading is carried out using cranes. Despite the development of loading and unloading technologies, cranes continue to be the basis of container ship handling technology.

The design of the latter involves the maximum use of the lifting capacity, and standard fastening means ensure the reliable installation of containers not only in cargo holds, but also on the deck in several tiers high.

The basic unit of capacity of cargo ships for transporting containers is TEU - a conventional unit equal to the volume of 1 20-foot container.

Modern ocean container ships have a capacity of 15-16 thousand TEU, that is, they are capable of taking on board 15-16 thousand 20-foot containers or 7.5-8 thousand 40-foot containers.

As a result, among all types of cargo ships, container ships are the largest today.

Types of container ships

Today, there are various classification criteria for container ships. One of them is based on the ships' belonging to a particular generation (period of construction):

- first generation 1956-1970;

- second generation 1970-1980;

- third generation 1980-1988;

- fourth generation 1988-2000;

- fifth generation 2000-2005;

- sixth generation 2006 - to the present.

Another classification division is by the method of handling ships in ports. The following types are usually distinguished:

LoLo

Such container ships have their own cranes on board, so they can carry out loading and unloading operations at unequipped berths or even at anchor when reloading containers onto barges and small floating craft.

RoCon

Universal vessels that combine the capabilities of a container ship and a RO-RO ferry. There are two options for the design of such vessels:

- in the first case, vehicles enter the holds under their own power, and containers are placed on the upper deck.

- In the second case, part of the vessel is allocated for rolling equipment, and part for containers (for example, the stern and bow, respectively).

It is worth noting that standard container ships do not have their own lifting equipment, which allows for the maximum use of usable areas for placing containers.

Division by passability

Depending on the size, the following types of ships are distinguished:

Panamax

The first container ship of this type was introduced in 1980. Their dimensions are optimized for passing through the Panama Canal.

Therefore, the hull length cannot exceed 294.1 meters and a width of 32.3 meters. The maximum draft in cargo is up to 12 meters.

With this geometry, ships are capable of carrying up to 4-5 thousand TEU.

Post-Panamax

These ships are no longer oriented towards the locks of the Panama Canal.

The first container ship of this type was the Regina Maersk, launched in 1996. Their capacity increased to a maximum of 6,400 TEU.

A real breakthrough in the design was the use of continuous guides, not only in the hold, but also extending onto the deck on several tiers.

Due to this, it was possible to eliminate the need to secure each container on the deck (saving on fastening materials, increasing the speed of processing).

Such container ships turned out to be so efficient that they account for about 30% of the entire container fleet.

Suezmax

The ships of this group are designed to pass through the Suez Canal, so their width is limited to 57 meters, and the draft varies between 14.4-16.4 meters.

The capacity of such container ships reaches 12 thousand TEU.

Post-Suezmax

These are larger ships with a width of up to 60 meters and a maximum draft in cargo up to 21 meters.

They cannot pass through the Suez Canal, so they work on ocean routes or go from Asia to Europe around Africa.

The capacity of such container ships reaches 18 thousand TEU.

Post-Malaccamax

These are the largest ships in the world that can pass through the Strait of Malacca.

They are limited to a draft of 21 meters.

They operate on the Singapore-Rotterdam route, since other ports in the world simply do not have the capacity to receive them.

Design features

In general, the design of the vessel does not have any fundamental differences from the cargo fleet used to transport other categories of cargo.

The power set is formed around the keel, most of the length of the vessel is occupied by cargo holds, the engine room is located in the stern, ballast tanks are provided along the sides in the lower part, and so on.

The main difference is the shape of the holds, almost rectangular to ensure maximum capacity and the presence of special guides for containers inside, along which it easily slides to its regular place.

Due to them, it is possible to significantly increase the speed of loading and unloading operations and ensure the correct placement of cargo.

At the same time, the condition of the guides must be maintained optimally to prevent damage to containers.

In most cases, ship cranes are absent, but some container ships, especially small ones, have their own cranes for unloading in unequipped ports.

Given the placement of containers on the deck, the hatch covers have a reinforced structure, while they must ensure the reliability of closing the holds to prevent moisture from penetrating inside.

The holds are made in the sizes of containers and have a clear division between them into compartments.

Often, certain design features of ships are characteristic of certain sizes.

The most compact are small feeders with a capacity of no more than 1 thousand TEU.

Traditional feeders are capable of taking on board up to 2 thousand TEU, and for Feedermax it is possible to transport containers in the volume of up to 3 thousand TEU.

Against the background of the high popularity of transportation of consolidated cargo, containers are a universal solution for almost every occasion, so the demand for container ships remains stable throughout the world. Moreover, in the future, the development of container transportation will continue without stopping.

Depending on the regions of navigation, all container ships are divided into two categories:

- Feeder ships operate on local lines with a length of no more than 500 miles. Their capacity does not exceed 1.5 thousand TEU.

- Mother ships are larger in size and serve longer routes.

- Position:

- Electrician engineer

- Position:

- Motorman

- Service date:

- December 29, 2025

- Position:

- Cook

- Service date:

- January 15, 2026